Winemaking

CHAMPAGNE, the most prestigious of sparkling wines

Wine-making at Saint-Sauveur

We have been harvesting and handling grapes in Saint Sauveur for over 120 years. Like all Champagnes, it is an AOC (Appellation d'Origine contôlée), on a delimited territory. We make it from three grape varieties: Chardonnay, Pinot Noir and Pinot Meunier, according to a rigorously defined vinification technology. After a year of work in the vineyards, the harvest arrives, usually in September.

In Champagne, the harvesting machine is absolutely excluded. According to tradition and regulations, the grapes are harvested by hand.

The size

the Cuvée and the Taille

The grapes are immediately taken to the press. In order to preserve the quality and avoid staining the juice, this pressing is gentle and progressive. We take care to press separately the grapes from different varieties, and also according to the slopes. The musts (juices) and later the wines obtained will have characteristics specific to their terroir. The cuvée, which represents the purest juice of the pulp, gives us wines of great finesse, rich in delicate aromas. The prunings give us more aromatic and fruity wines.

By separating cuvée and size, grape varieties and terroir, we will have a whole palette of wines at our disposal for the creation of our blends.

Heading for the press

Cleaning of stainless steel tanks

The Champagne method

After the blends are made, the wines are bottled. A small amount of sugar in the form of liqueur and yeast are added.

The bottles are then closed with a plastic cover, called a "bidule", and held in place by a metal cap. The drawn bottles are immediately lowered into our chalky cellars and kept at a constant temperature of 12 to 13°.

The second fermentation then begins, a delicate operation to obtain a fine foam and allow the aromas to develop.

At the end of the fermentation process, the yeasts gradually die off and form a deposit that contributes to the maturity of our Champagne for several years in the cellar.

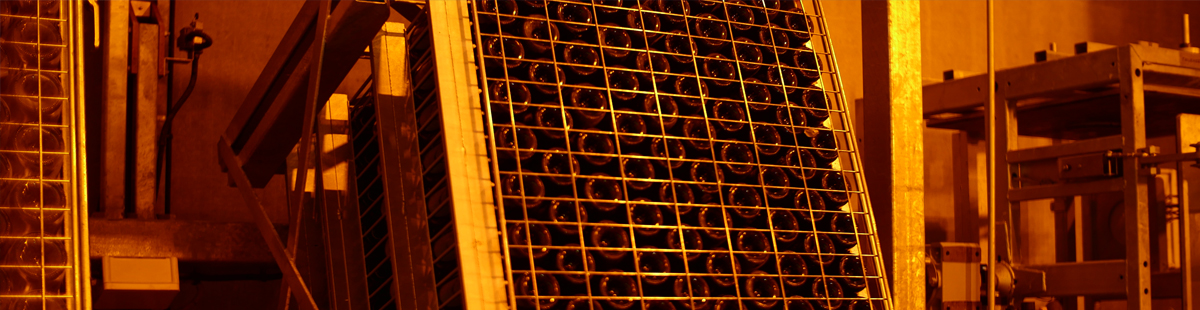

Bottles on slats

Disgorgement

This operation consists of expelling the deposit, which was brought into the neck of the bottle by the stirring process, now mechanised with the gyropallet system.

At this stage, we add the liqueur d'expédition, which will sweeten our wines to obtain brut, demi-sec or dry Champagne.

Bottles on slats

Finally comes capping

A cork is held in place by a metal wire, the bottle is then dressed